Bread crumbs machine

For more information of bread crumbs machine please click here:bread crumbs machine

Firstly, about us:

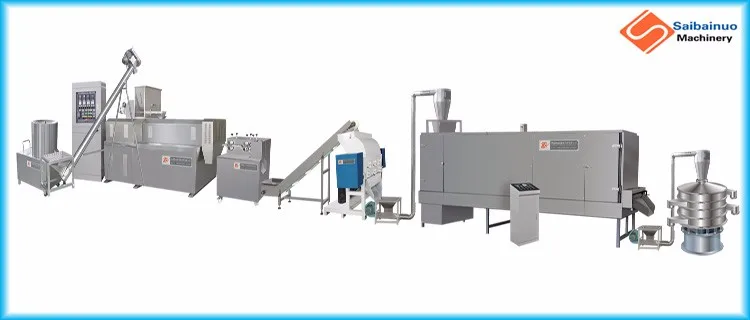

Saibainuo is a leading manufacturer (nearly 20000 sqaure meters) of high quality

twin screw and single screw extruders for food industries.We have almost ten years’

experience of working with our customers providing specialist designs and practical

solutions for a wide range of process needs.We have been supplying the most

efficient equipment available to snacks food manufactures around the world,so

welcome to our factory, you will have a worthy jounery.

Saibainuo Machinery

Food Machinery--High quality.Factory price!

Email: extruder@foodmachine.cc

website: www.china-food-extruder.com

Phone(Whatsapp): +0086 18668988231

1.2016 hot sale bread crumbs/panko making machine/production line description:

1)

Bread Crumb Making Machine is researched and developed on the basis of international

advanced technology. The performance and quality have reached the highest domestic

level of the same line. The line changes the traditional making process. From mixing

materials, extruding, cutting, drying to the finished products are done in one

automatic line.The bread crumb is widely used as food coating additives on the

surface of frying food like: frying chicken, fish, sea foods (shrimp),onion ring etc.

The taste is fragrant, crispy, delicious and no rich nutrition.

2)

Raw material:for bread crumbs production.It is from powder for wheat flour to bread

crumbs automatically. No bread produced during the whole process.So no bread crust

appeared. The final product is bright white and with good texture.

3)

Application:food additive for deep fried food,and mainly for frying food surface,

such as:fried chicken, fish, seafood (shrimp), chicken,chicken wings,onion rings,etc.

Its feature is crispy soft, tasty, delicious and nutritious.

4)

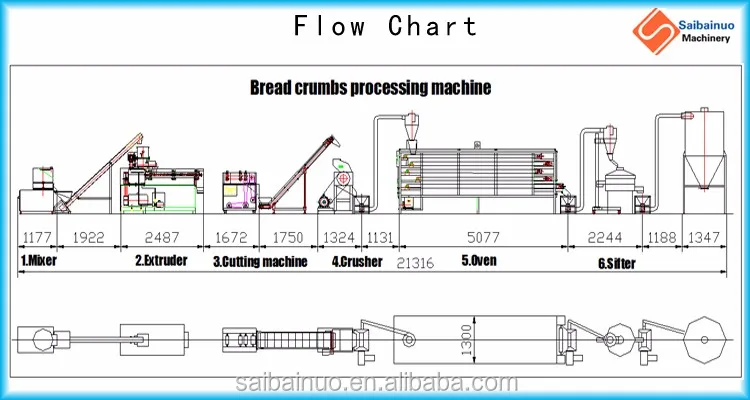

Flow chart:

Mixer-Screw conveyor--Twin screw extruder-Cutter-Hoister-Humid crusher-Air conveyor

-Multi-layer roasting oven-Air conveyor(or vacuum feeding machine)-Grading sifter.

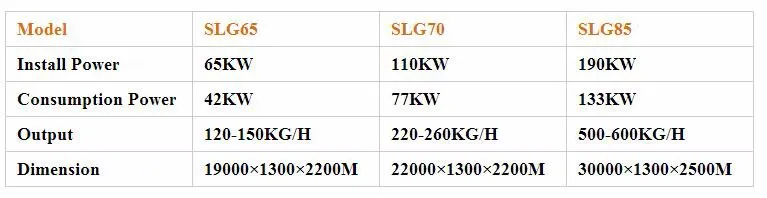

5)Capacity: find below form.

6)

Voltage:Three phases:380V/50HZ,Single phase: 220V/50HZ,we can make it according to

customers' local voltage of different countries.

7)Machines Materials: All the machines are made by food grade stainless steel.

For more information of bread crumbs machine please click here:bread crumbs machine

2.The specification of the bread crumbs/panko making machine/production line:

3.The bread crumb samples:

4.The drawing of the bread crumb: side view and top view

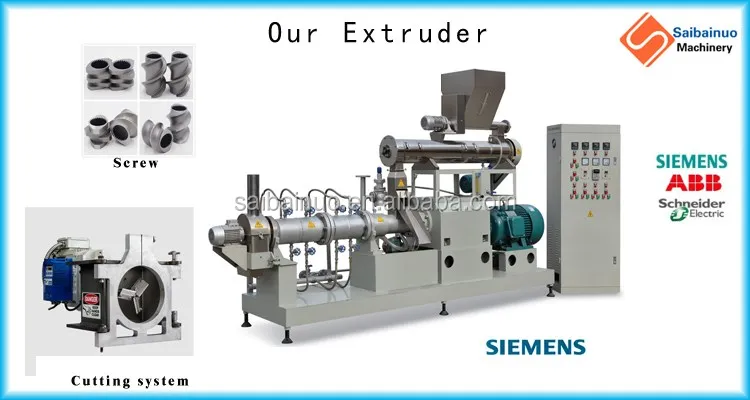

a.Various models to meet different output capacity requirements.

b.Flexible configurations to meet different produce, budget and workshop layout

requirement.

c.Vast raw material range to produce different final products by only one

production line.

d.High automation and accurate control system to save labor cost and improve the

quality of final products.

e.Independent temperature control system is able to realize zone temperature

control,electronic induction, accurate & visual digital display.

f.Feeding system without material returning.It is unnecessary to clean barrel and

screw in case of restarting or material replacement.

g.Screw adopts high-performance nitride alloy steel with strong wear-resistance

and longer service life.

h.Food-grade stainless steel. Neatness and easy clean.

Saibainuo Machinery

Food Machinery--High quality.Factory price!

Email: extruder@foodmachine.cc

website: www.china-food-extruder.com

Phone(Whatsapp): +0086 18668988231

For more information of bread crumbs machine please click here:bread crumbs machine